ANSYS Mechanical

High-fidelity structural simulation for faster, safer, and more reliable product design

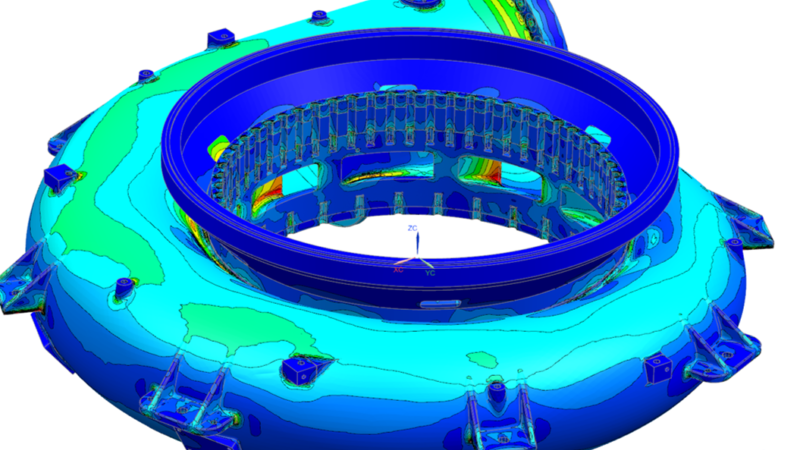

ANSYS Mechanical is a powerful finite element analysis (FEA) environment that helps engineers predict how components and assemblies will behave under real-world loads and conditions—before any physical prototype is built. As product complexity increases, ensuring structural integrity, durability, and performance becomes difficult and time-consuming when relying on trial-and-error iteration. ANSYS Mechanical streamlines this process by providing robust modeling tools, advanced solvers, and clear post-processing to evaluate stress, deformation, contact, and failure risks with confidence.

With capabilities ranging from linear analysis to advanced nonlinear and multiphysics-ready workflows, ANSYS Mechanical supports reliable decision-making across industries such as aerospace, automotive, energy, industrial equipment, and electronics. Engineers can validate designs earlier, reduce redesign loops, optimize weight and cost, and accelerate development cycles—while maintaining accuracy and traceability in demanding engineering programs.

Why ANSYS Mechanical?

- Accurate structural prediction for complex parts and assemblies

- Efficient setup with smart meshing and geometry preparation tools

- Robust contact modeling for real-world interfaces and assemblies

- Scalable solvers for fast turnaround on workstation and HPC

- Clear post-processing for engineering decisions, reporting, and review

Core analysis capabilities in ANSYS Mechanical:

- Linear static analysis (including bolt pretension and contacts)

- Modal (natural frequency) and harmonic response analysis

- Buckling analysis (linear and advanced workflows)

- Transient structural dynamics (time-dependent loading)

- Nonlinear analysis (material, geometry, and contact nonlinearities)

- Thermal-structural workflows (temperature effects on stress/strain)

- Fatigue life estimation (stress-life / strain-life methods)

- Composite modeling and failure criteria (module-dependent)

- Fracture mechanics and crack growth (module-dependent)

- Design studies, parameter sweeps, and optimization workflows